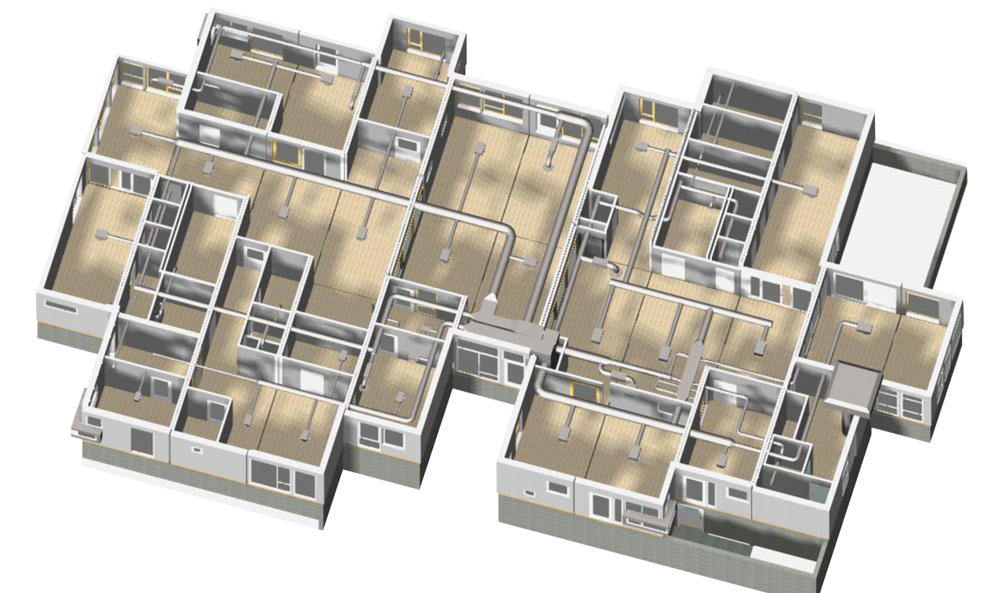

ArchiFrame is the reason we chose Archicad – ArchiFrame expands the already flexible and user-friendly Archicad workflow with the production of necessary machining files (CNC) to be used in our highly automated factory.

Matius Henriksen Indrestrand

Construction and project planning, Støren Treindustri AS

With ArchiFrame we can keep everything inside Archicad. From architect to factory, design, engineering, production and build: everything is within the same program.

Moreno Vrijma and Casper Stinenbosch

Designis, Netherlands

We use ArchiCAD and ArchiFrame to produce structural drawings for wooden houses, and for element and module production. I can recommend ArchiFrame for similar use.

Allan Møller

Prosjekteringsavdeling / Designing Department, Skanska Husfabrikken AS