Background

Space Factory builds energy-efficient, affordable homes and is an innovator in sustainable residential architecture. The company is especially known for its modular house designs.

The company is currently investing in automation and new factories to increase productivity and is very keen to combine great technology with efficient workflows. Sustainability is a big priority for Space Factory, and using the right hardware and software helps meet sustainability goals and targets.

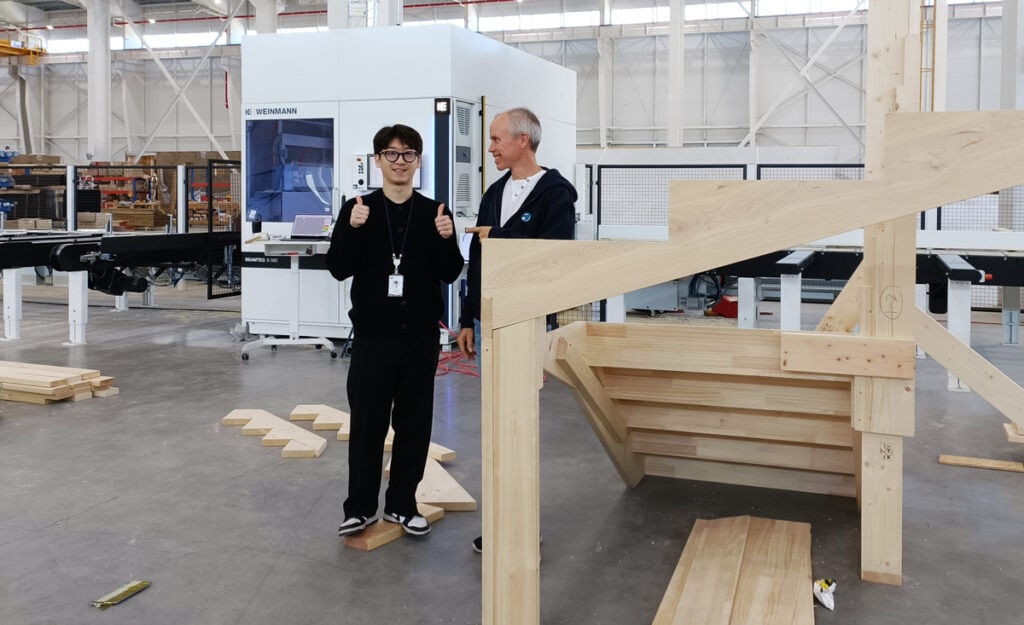

Space Factory acquired and set up a new state-of-the-art timber factory ready for production in the autumn of 2024 and needed the perfect timber engineering solution to go with it…