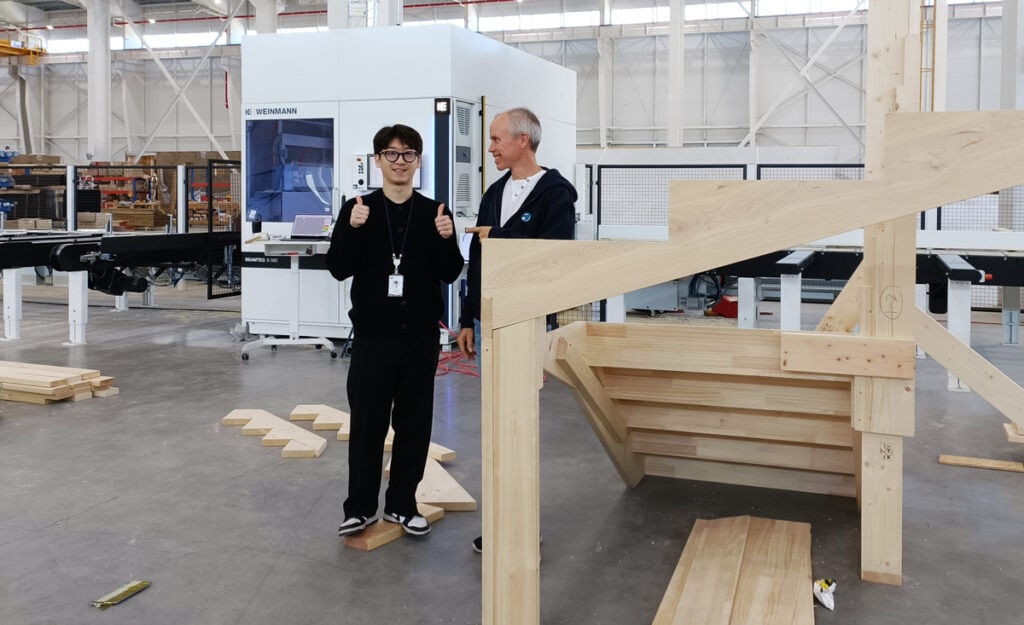

The construction industry is on the brink of a technological revolution, and one our customers in Korea, Space Factory, is at the forefront of this transformation. This video offers a fascinating glimpse into how automation and robotics are redefining the way we build.

From modular construction to advanced robotic fabrication, Space Factory is pioneering innovative solutions to streamline efficiency, reduce waste, and push the boundaries of what’s possible in architecture and construction.

Meet Space Factory

Space Factory is a cutting-edge company dedicated to revolutionising construction through automation, robotics, and modular design. Their approach integrates robot-assisted fabrication, CNC machining, and AI-driven design optimisation to create high-quality, sustainable structures at an unprecedented pace. Read more about how Space Factory is innovating with ArchiFrame, GranIT and Weinnmann here: https://archiframe.fi/en/news/archiframe/future-of-sustainable-architecture/.

Robotics in Modular Construction

Robotics and automation are changing the game for modular construction. Robotic arms and automated assembly lines handle everything from precision cutting of materials to structural assembly, significantly increasing speed and accuracy while minimizing material waste.

CNC Precision

CNC machines like those from Weinmann enable the automated production of custom, high-precision components with minimal human intervention. This not only ensures a perfect fit for each module, but also significantly reduces the errors commonly associated with traditional construction methods. Additionally, it allows for higher production volumes with a smaller labor force. High-quality CNC files—such as those generated by ArchiFrame, WUP for the Weinmann framing station, and BTL for Weinmann cut saws—are fed into the GranIT MES system. This system optimizes efficiency by combining multiple short walls into a single long wall for streamlined production. The GranIT system is used to manage and control the entire factory operation.

Digital Twin Technology

Space Factory utilizes digital twin technology to optimize building designs before construction even begins. These advanced digital models allow for the early identification of structural challenges, improved efficiency, and real-time design modifications without interrupting the production process. This is where ArchiFrame and GranIT play a key role—streamlining the entire pipeline from design to production. Using precise models created in Archicad with ArchiFrame, Space Factory can accurately calculate the exact quantities of all raw materials needed, from 2×6 studs and OSB/gypsum boards to even nails and staples.

Sustainable and Efficient Building Practices

By utilizing robotic automation, Space Factory dramatically reduces construction waste and energy consumption. The ability to fabricate off-site in a controlled environment also cuts down on transportation costs and site disturbances, making it an environmentally friendly approach to building.

The Future of Construction

The integration of robotics, AI, and modular construction is set to redefine industry standards. Companies like Space Factory are proving that automation isn’t just a futuristic concept—it’s happening right now. The benefits are clear:

- Faster project completion times

- Greater precision and quality control

- Reduced labor costs and material waste

- Increased sustainability

As the demand for affordable, high-quality, and sustainable housing grows, factories like Space Factory will play a crucial role in meeting these challenges head-on.